Switched to Firefox from Safari on my MacBook and want to give these one more try.

Continued.....

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| Pin Turning tutorial (pics) http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=15047 |

Page 1 of 2 |

| Author: | Kevin Gallagher [ Tue Dec 18, 2007 10:12 pm ] |

| Post subject: | |

Switched to Firefox from Safari on my MacBook and want to give these one more try.

Continued..... |

|

| Author: | Kevin Gallagher [ Tue Dec 18, 2007 10:27 pm ] |

| Post subject: | |

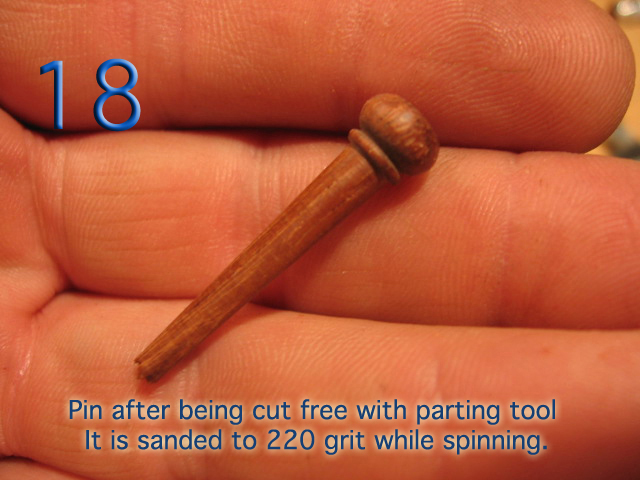

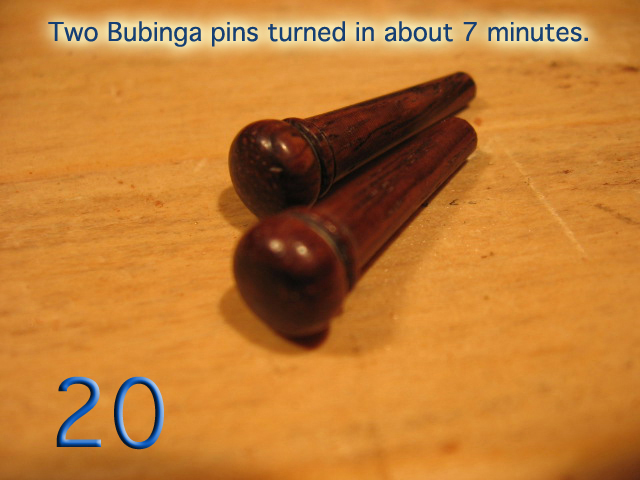

...Here are the final tutorial pics...

Thanks for looking and sorry for the broad strokes, but this process can be adjusted to suit individual preferences and tooling. Regards, Kevin Gallagher/Omega Guitars |

|

| Author: | Kevin Gallagher [ Tue Dec 18, 2007 10:31 pm ] |

| Post subject: | |

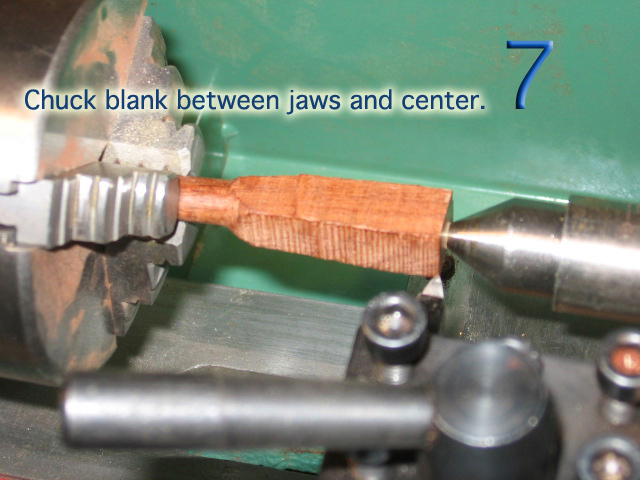

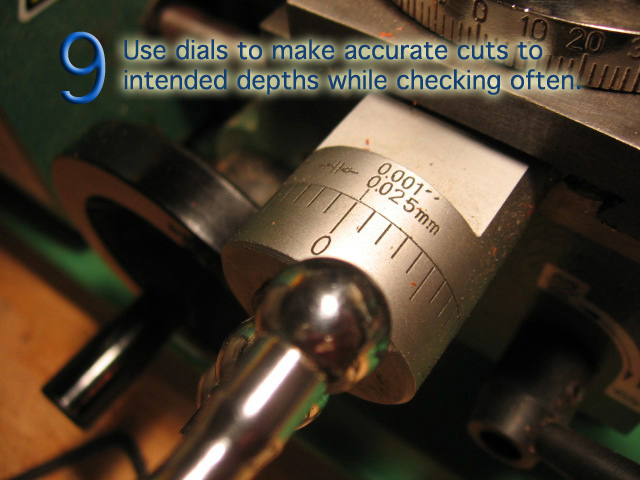

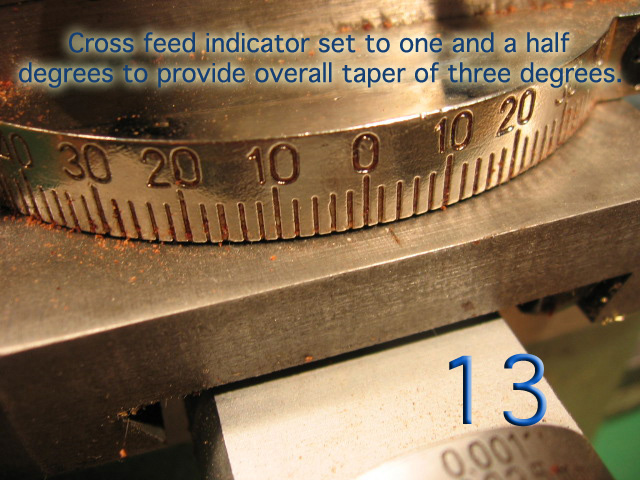

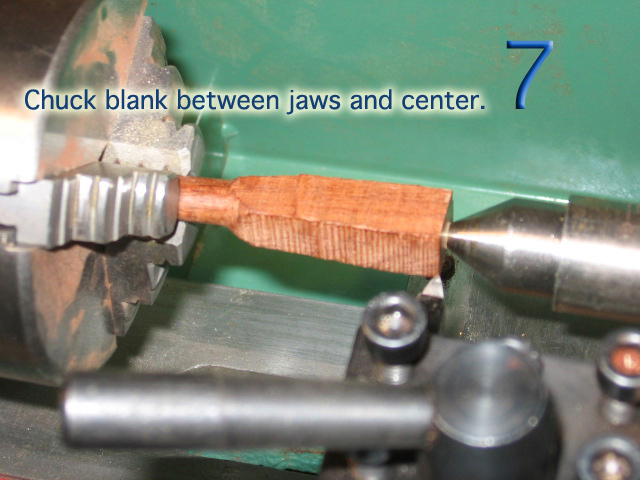

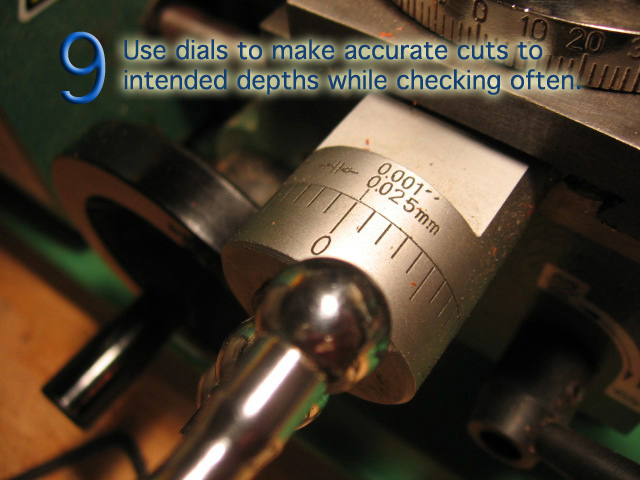

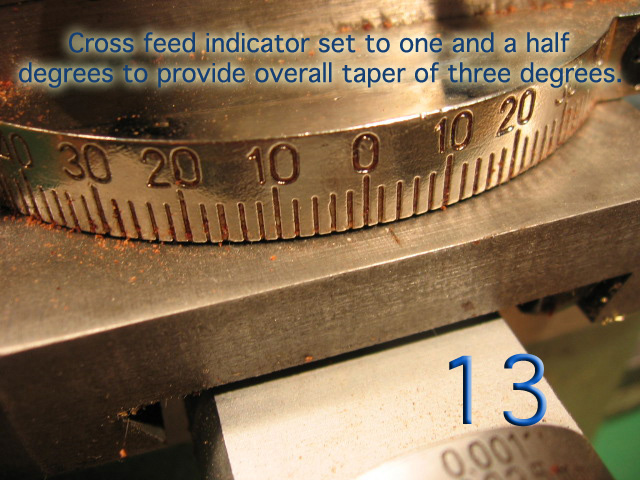

It's possible to get good results using a wood lathe and steady rest, but the taper and diameters are important and accuracy is necessary to provide a good fit and solid integration between the pins and the bridge. For that reason, a machine lather with cross feed are the best choice. Regards, Kevin Gallagher/Omega Guitars |

|

| Author: | John K [ Wed Dec 19, 2007 12:30 am ] |

| Post subject: | |

Thank you Kevin. I have been wondering about this very thing. Turning pins out of woods that match the body binding etc has been a goal of mine and I could not decide what kind of lathe to buy. I am curious about the specially ground head cutter. Did you do that or did you have it done? Do you have the model number of that Grizzley lathe? John |

|

| Author: | Hesh [ Wed Dec 19, 2007 12:53 am ] |

| Post subject: | |

Very nice job Kevin!

|

|

| Author: | Terry Stowell [ Wed Dec 19, 2007 12:56 am ] |

| Post subject: | |

Thanks Kevin. I appreciate the time you just invested. Many happy reaps & returns! |

|

| Author: | Bill Greene [ Wed Dec 19, 2007 12:56 am ] |

| Post subject: | |

Outstanding Kevin...thanks greatly for all the time it takes to put things like this together. Happy Holidays and Merry Christmas for you and yours! |

|

| Author: | Kirt Myers [ Wed Dec 19, 2007 1:35 am ] |

| Post subject: | |

My thanks too, Kevin. And thanks for everything you do here. I'd like to try that someday, so this is going into my library. Happy Holidays |

|

| Author: | burbank [ Wed Dec 19, 2007 1:41 am ] |

| Post subject: | |

Thanks, Kevin, very educational. |

|

| Author: | TommyC [ Wed Dec 19, 2007 1:52 am ] |

| Post subject: | |

That was neat Kevin, thanks. |

|

| Author: | Louis Freilicher [ Wed Dec 19, 2007 9:03 am ] |

| Post subject: | |

Nice Tutorial Kevin. It looks like we posted within a day of each other but it's great to see different approaches to the same job. Now, do you have a pic of the Monarch? (drool?!) Louis |

|

| Author: | Kevin Gallagher [ Wed Dec 19, 2007 9:04 am ] |

| Post subject: | |

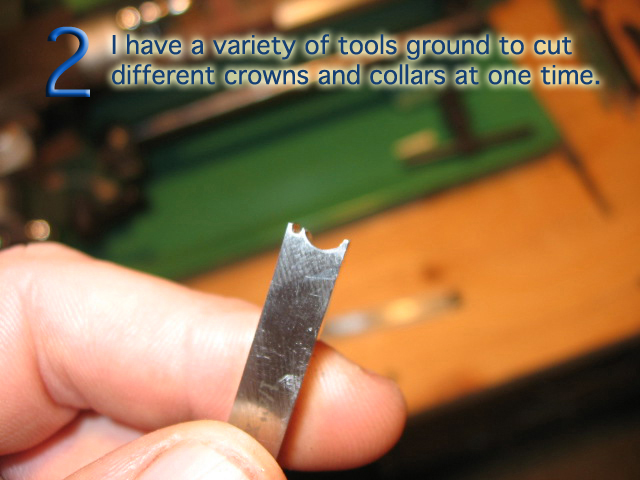

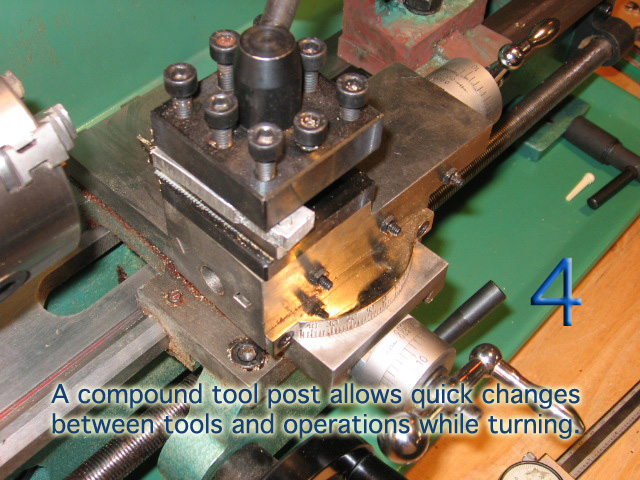

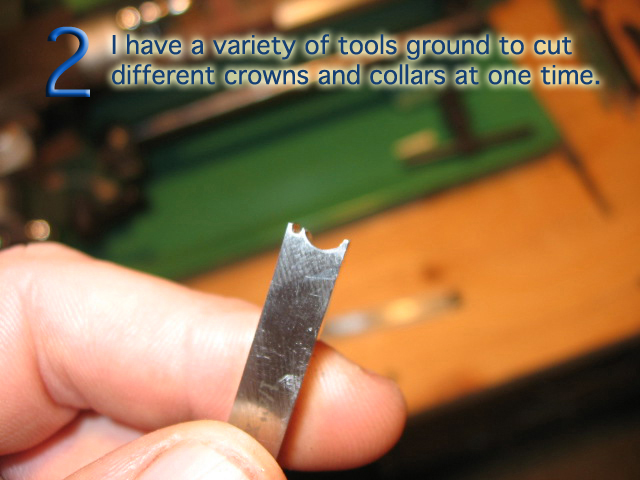

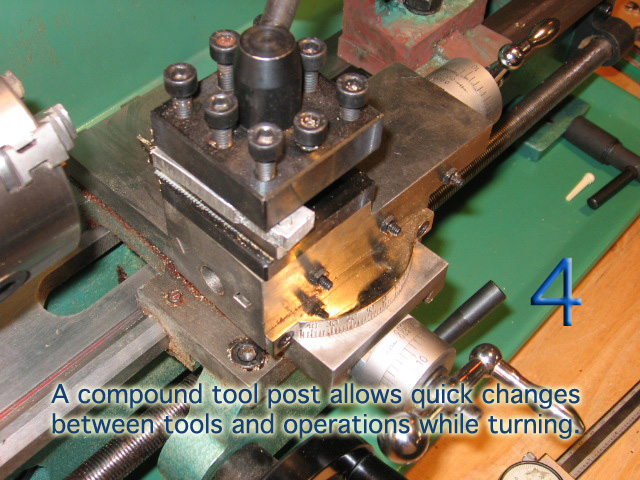

Thanks for taking a look to those who have. My intial post attempt seems to have gotten more looks than this successful one, but this one is a little more fun to look at than all those funny little question marks. I apologize again that it wasn't nearly as detailed as it could have been, but we could post photos all day long about pretty much anything we do in our shops. JohnK, I just cut those specialty cutters out of high speed steel cutter blanks. I cut this one just for the tutorial, but i have about a dozen that give me different crown and collar dimensions and radii. I also have a one pass cutter that cuts the entire pin from cap to tip in one operation. I have only use it a few times since it really pulls on the small diameter piece. Results are good with it, but i've found that I have to chase the taper to true it up after using it anyway so I just use a method close to what is pictured here. That little Grizzly is nice and small. The model number is G8688 7" x 12" Mini Metal Lathe. It's nice and solid and the cross slide and steady rest are true and fully adjustable as far as gib and nuts go. The turret post works well, too. The only accessories that I'd recommend picking up right away are the drill chuck with an MT#2 taper for drill on center from the tailstock and a nice slection of 5/16" HSS cutter blanks and precut cutters. Regards, Kevin Gallagher/Omega Guitars |

|

| Author: | WaddyThomson [ Wed Dec 19, 2007 9:18 am ] |

| Post subject: | |

For purposes of tool cutting, what clearances are needed for wood cutting tools. Do they differ from metal cutting angles? i.e., what is the tip angle to the wood for optimal effect, and how much of an angle on the bottom edge under the cutting edge? |

|

| Author: | Terence Kennedy [ Wed Dec 19, 2007 1:24 pm ] |

| Post subject: | |

Wow, very cool Kevin. Terry |

|

| Author: | Howard Klepper [ Wed Dec 19, 2007 1:36 pm ] |

| Post subject: | |

Thanks Kevin. |

|

| Author: | David Collins [ Wed Dec 19, 2007 1:45 pm ] |

| Post subject: | |

Nice Kevin. This is something I've been meaning to take up for some time now, and I'll be sure to bookmark this for reference when I do. |

|

| Author: | John K [ Wed Dec 19, 2007 1:49 pm ] |

| Post subject: | |

many thanks Kevin. I appreciate the tips and the lathe info. John |

|

| Author: | Bruce Dickey [ Wed Dec 19, 2007 4:12 pm ] |

| Post subject: | |

Excellent Kevin. Super Tutorial, good enough to hang six steel strings on anytime! I think Kevin just treated us to another OLF BAR-RAISING.

I'm beginning to think next we'll see someone making tuners in the next Tutorial..... |

|

| Author: | KenMcKay [ Wed Dec 19, 2007 8:17 pm ] |

| Post subject: | |

Great tutorial! thanks a lot. I would like to make some violin pegs and that looks like it would translate. |

|

| Author: | Kevin Gallagher [ Thu Dec 20, 2007 12:51 am ] |

| Post subject: | |

Louis, My Monarch has been in storage since I moved into the shop i'm currently in. I just don't have the room for it since it does have a big footprint. It's a 1970 EE 10"X20" Toolmakers Lathe and I had to run a static convertor to keep it running with the stock motor in my old shop. I remember the day that the truck pulled into my Grandfather's machine shop to deliver it...brand new and coated with more Kosnolene than i'd ever seen smeared on anyhting. Cleaning machines on the shop floor was one of my small jobs in his shop, but i also got to remove this messy rust inhibitor from any new machines that came in. I probably put 3000 hours on this little beauty while it was in his tool room. My Grandfather died just two years later when I was only twelve and his shop stayed in business with my uncles running (or destroying) it for the next 6 years or so. When they were closing the shop when i was 20, knowing how much i loved running that little Monarch, they called to offer it to me for $2000.00, but my Grandmother made them give it to me for free since she was still the actual owner of the business. I also grabbed three Bridgeport mills, an EDM unit, a Cinncinati Radial Drill Press and a pair of Hardinge HLV-H model lathes since I had an empty truck with me and the permission of Grandma to take whatever I wanted before the new tenants took over the shop building. The Hardinge pieces were slightly more accurate than the Monarch, but not quite as heavily built. I added a Sony Magnascale two axis readout to it and am actually thinking about pulling it off to retrofit it to my little Grizzly. Anyway, I still own all of these machines except the Cinncinati drill press and have stored them for most of the past 15 years, with the exception of the Bridgeports and the Monarch. I keep a small 1 hp in my shop and used to keep a #1 and #2 Versi-head out in my old shop. All have been reworked to run wood or metal and all have at least one axis covered by some sort of digital readout. I'm hoping to move into a much larger shop again in the future, but with the year long layoff caused by the injury to my shoulder last year, it will be quite some time. Maybe when it's time for me to be retiring, I'll finally have the shop I want. I don't get down to where they are all stored in New Jersey very often, but will snap a photo or two next time I do. Once i'm able to pull them out again, I'll experienced some fond memories of days in Grandpa's shop as I start to wipe the Kosmolene off of them to fire them up again. I like your Hardinge unit and am sure it really works well for you. Thanks, Kevin Gallagher/Omega Guitars |

|

| Author: | npalen [ Thu Dec 20, 2007 3:21 am ] |

| Post subject: | |

Kevin--As an old machinist, I'm drooling over all the machinery you describe even without seeing it. I have a little Grizzly 9X24 bench lathe that I would be lost without. Would love to have digital readouts on it. Life is way too short to not have every tool possible to enjoy. Nelson |

|

| Author: | Kevin Gallagher [ Thu Dec 20, 2007 5:37 am ] |

| Post subject: | |

Nelson, You know, it's funny that no matter how many tools or machines we have, our list of tools and machines that we want never gets shorter.....My wide comments on this phemomenon every time I set my sights on getting an addition to my shop or auto machanic tools. I still have boxes and boxes of unopened cutters of HSS and Carbide and all sorts of insert holders and inserts for them in that storage bin with my machines. A family friend has a huge storage area in New Jersey and has allowed me to have a 15 ft. X 40 ft. slice of it for years at no charge or i would have sold all of these machines to save the storage costs. Steel benches, shelves and things were the only pieces remaining in my Grandpa's shop when the new folks moved in. I was able to grab a few that I have in my shop to this day. They had stacked tham out by the street back then with big "FREE" signs on them. I was also able to confiscate all of the shop measuring tools like outside, inside and depth micrometers and all of the vernier calipers from 6 inch all the way up to 48 inch. They're all Starrett tools sinc emy Grandfather wasn't buying the new Mititoyo tools that were flooding the market back in the 70s. He was old school. I don't do much actual machinist work anymore, but still love the machines and tools from those days. They are treasures that I fear my sons will never truly apreciate the value of. You never know, though, my 16 year old just finished his first guitar and it is a beautiful piece. He wants to build behind me. If I ever sell any machines I'll be sure to let you know, but at 3000 pounds, even that "little" Monarch EE is a bear to move. Thanks and regards, Kevin Gallagher/Omega Guitars |

|

| Author: | Howard Klepper [ Thu Dec 20, 2007 6:25 am ] |

| Post subject: | |

I'm jealous of your getting to grow up in a machine shop. When I was in high school, I had the stigma of being labeled as college-bound, which meant that I took all academic electives instead of machine shop. It has handicapped me to this day as I play catch up trying to teach myself machine skills. |

|

| Author: | WaddyThomson [ Thu Dec 20, 2007 6:52 am ] |

| Post subject: | |

I wish I had paid more attention when I was growing up. I know enough to be dangerous. I sold my dad's South Bend 9" swiing lathe when I had to clean out the house. I kept the little Craftsman (Atlas) 6" swing, because he had given it to me, and it is older than I am. It is a nice little lathe, but is the old style, and not as heavy as some of these newer machines. I do have a milling attachment for it though, so maybe I can put it to use, if I can ever figure out how to use everything. I know enough to do basic machining stuff, but not cutting threads, and such. It has automatic feed, but I can't say I've used that feature either. I need to look at it to see if it will do tapers. I'm sure it will. I have just never known how, until now. |

|

| Author: | Louis Freilicher [ Thu Dec 20, 2007 8:08 am ] |

| Post subject: | |

Kevin, Thanks for sharing that wonderful piece of family history with us. My dad's dad was a sculpted and art teacher in his day and while he passed before I reached my teens I do remember spending a summer or two in his studio in southern California learning to do relief carving. Years later my grandmother sent me all his chisels and carving tools, many of which still see use in my shop carving arch plates and such. I hear what the old timers say about Monarch's over on the PM forum, so I had to ask. The Heavier the better in terms of surface finish, just don't ask me to move it! Cheers, Louis |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|